Discrete and Process Manufacturing

Acumatica Production Management

Home » ERP Resources » Acumatica Resources » Acumatica Production Management

Support Multiple Types of Manufacturing with Confidence Using Acumatica Manufacturing Edition Production Management

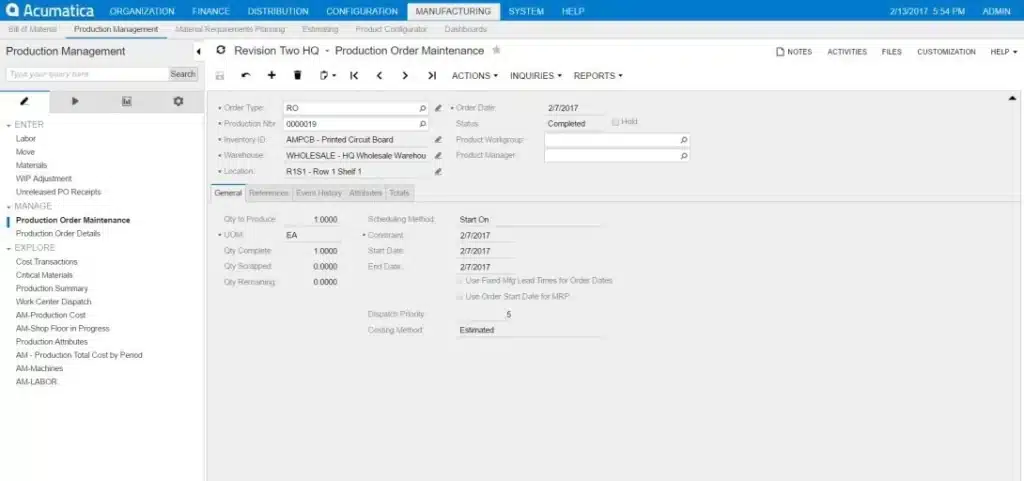

The Production Management module, part of Acumatica’s Manufacturing Edition, allows for the ability to track material and labor costs, schedule production on the shop floor, and allows the user to compare the estimated/planned/standard production costs to the actual costs of the production order.

PRODUCTION ORDER TRACKING

- Captures total manufacturing costs for a production order, including material, labor, machine, tool, overhead, and outside processes.

SCHEDULING

- Multiple scheduling options allow you to meet your customer’s delivery dates.

- The system utilizes both forward and backward scheduling methods to allow flexibility.

- For project-centric manufacturers, Project Accounting creates production orders from project tasks, and updates projects with manufacturing information

Key Benefits

COORDINATE ACTIVITIES

- Manage your entire business with complete real-time information on your operations

- Coordinate labor, machines, and inventory and optimize your company’s processes

STAY ON ONE PLATFORM AS YOU GROW

- Adapt the software to your changing needs

- Leverage powerful features and functions for multiple production environments

HANDLE PRODUCTION ORDER CHANGES EASILY

- Build prior or alternate Bills of

- Material revisions

- Substitute operations and/or materials on a production order

ENHANCE LOT/SERIAL TRACKING

- Full lot and serial traceability throughout an item’s lifecycle

- Lot and serial numbers can be assigned or manually entered using purchase receipts, inventory issues, and shop floor control transactions

Features and Capabilities

CRITICAL MATERIALS

LABOR TRACKING

Capture direct production labor to production orders by employee. Enter and track non-production time using indirect codes.

BACKFLUSHING

Eliminate reporting by backflushing labor or material when reporting the production quantity completed, useful when a company only wishes to record the production quantity.

MATERIAL TRACKING

Issue stock and non-stock materials and parts to a production order. Capture lot and serial numbers on controlled items.

PRODUCTION PERFORMANCE

Monitor and manage performance with detailed reports, including actual vs. standard/planned costs by detailed element, including labor, material, machine, tools, fixed, and variable overheads.

EVENT AUDIT TRAIL

Trace all production activities (events) against a production order including description, date and time, and ID of the user.

PRODUCTION ORDER CHANGES

Manufacture to prior or alternate bills of material revisions, substitute operations and materials as desired.

MULTI-SITE

Support multiple sites and have the flexibility to have different or alternate BOM/Routing for each different site.

LOT AND SERIAL TRACKING

Maintain full lot and serial traceability throughout the lifecycle of the item. Capture lot and serial numbers at purchase receipt, inventory issues, and shop activity transactions.

BARCODE INTEGRATION

Use barcode data collection to record labor and material transactions as well as inventory transactions including issues, receipts, cycle counting, and physical inventory