Discrete and Process Manufacturing

Acumatica Bill of Material / Routing

Home » ERP Resources » Acumatica Resources » Acumatica Bill of Material BOM

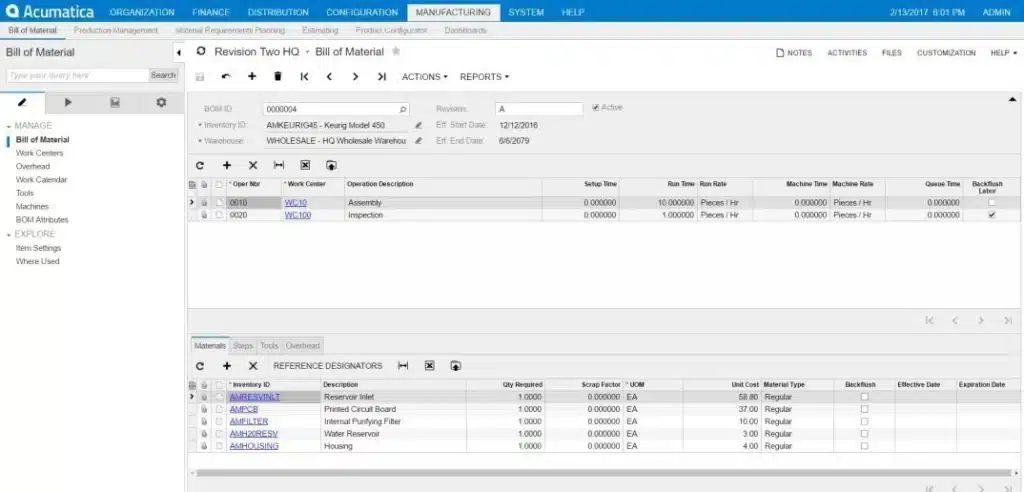

The Bill of Material (BOM)/Routing module, part of the Acumatica Manufacturing Edition, creates production specifications and is the framework for the planning functionality in all Acumatica Manufacturing Edition modules. Maintenance of the BOM/Routing information is performed through a single screen.

INTEGRATED BOM/ROUTING

- Directly connect materials, work instructions, attributes, and overhead costs to an operation

- Allow for the time-phased release of materials.

MULTILEVEL BOM/ROUTING

- List the components required to produce an item, as well as any sub-assemblies and their components.

- Provide both an engineering and a costed view of the entire product structur

Key Benefits

COORDINATE ACTIVITIES

- Manage your entire business with complete real-time information on your operations

- Coordinate labor, machines, and inventory, and optimize them for your company’s processes

STAY ON ONE PLATFORM AS YOU GROW

- Adapt the software to meet your changing needs

- Leverage powerful features and functions for multiple production environments

GAIN TOTAL CONTROL OF REVISIONS

- Maintain a complete revision history of your BOM/Routing

- View multiple revisions, both past and future

- Identify the reasons for each revision

SUPPORT ALL YOUR COSTING METHODS

- Allow for multiple costing methods:

- average, standard, and actual

- Add tooling costs and overhead costs, both fixed and variable

Features and Capabilities

EFFECTIVITY/EXPIRATION DATES

Control material planning and usage according to effectivity dates for phase-in and phase-out of content changes.

PRODUCTION STEPS

Document the entire process using detailed work instructions and standard note capability for each process step.

WHERE USED

Allows for components on Bills of Material to be displayed where they are used on a single-level or multi-level basis.

PHANTOMS

Use phantom items to simplify structure maintenance for related groups of parts and materials to multiple products. If you create a planning bill of material, your planning and production teams can “skip over” phantoms to plan and allocate components.

REFERENCE DESIGNATORS

Relate BOM component parts to the drawing’s part numbers to avoid confusion and duplicate entry in the bill of material.

MULTIPLE SITES

Enables the support of multiple sites and have different or alternate BOM/Routing for each different site.

BOM COST ROLL

Use flexible cost roll for a single-level or multi-level BOM, by item or site. Costs of the lower-level item will “roll” into the costs of the higher-level items. In a standard cost operation, costs will update the pending standard cost for each item in inventory.

FLEXIBLE COPY BOM

Copy an existing BOM/routing to a different item as an alternate BOM/routing or for easy setup for a new, similar item.

MASS CHANGE

Allows for the replacement of a component with a different component on individual or all Bills of Material.

ATTRIBUTES

Used to display optional or required values when reporting production. These are available on the bill of material header and/or operations and can be copied onto a Production Order when the order is created.