Distribution and Inventory

Acumatica Inventory Management

Home » ERP Resources » Acumatica Resources » Acumatica Inventory Management

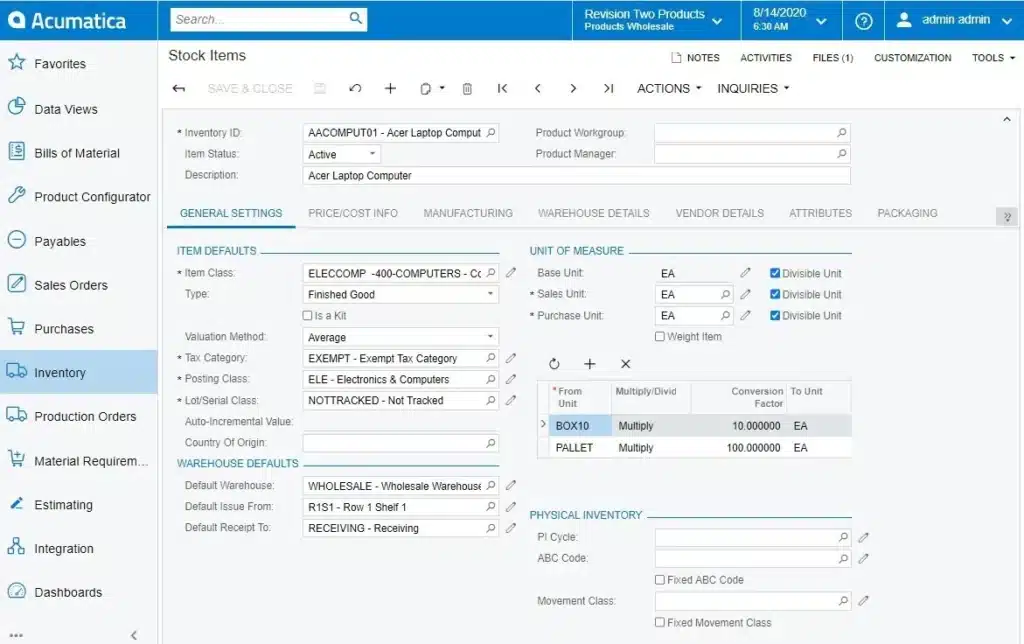

Control system-wide inventory to manage your distribution process efficiently and without losing track of costs. Receive inventory to a specific location and drill down to change item default lot/serial numbers, valuation methods, accounts, and more.

INVENTORY MANAGEMENT FOR THE WAY YOU DO BUSINESS

- Locations: Manage multiple warehouses with location-specific inventory quantities, allocations, availability, and costs. Define bins, use carts for picking and put-away, and set default locations for inventory transactions such as receipts, customer returns, and shipments. Use movement classes and ABC codes to optimize warehouse locations for high volume and low volume products.

- Item Management: Streamline item creation and maintenance with sub-items for like products and matrix items for products with attribute variables. Build kits to stock or to order with flexible disassembly features. Setup cross-references between internal, customer, and vendor items with unit of measure conversions.

- Inventory Management. Automatically distribute inventory from a central warehouse to other locations upon receipt. Automate replenishment using min/max, economic order quantities (EOQ), safety stock, seasonality, lead times, and other information to minimize carrying costs while maximizing fill rates and turns. Achieve unprecedented inventory accuracy with barcode scanning and physical inventory.

- Lot and Serial Numbering: Track inventory by lot or serial number. Enter lot or serial numbers on receipt, issue, or assembly. Define shelf life for perishable inventory with expiration dates and first-expired-first-out picking.

- Integrated Processes: Inventory Management integrates seamlessly with General Ledger for financial reporting. Improve purchasing, sales, projects, field service, and manufacturing activities with automation, scheduled tasks, and custom workflows across the system.

- Multiple Valuation Methods: Use standard cost, moving average, FIFO, and item-specific methods. Select a different valuation method for each inventory item. Make direct adjustments to cost and physical inventory count using report and inquiry screens.

Key Benefits

OPTIMIZE INVENTORY

- Use replenishment and automation to increase inventory turns.

- Improve inventory accuracy with barcoding and physical inventory

IMPROVE CUSTOMER SATISFACTION

- Honor contracts and fulfill orders as promised with real-time access to inventory levels and customer- specific pricing

- Manage inventory effectively to avoid stock-out situations.

MANAGE COSTS

- Accurately track costs of goods sold and inventory carrying costs.

- Reduce rush orders, identify low-cost vendors, minimize freight charges, and reduce write-offs for expired or obsolete inventory.

IMPROVE DATA ACCURACY

- Eliminate manual data entry with integrated processes and barcode data capture.

- Reduce errors with default settings for accounts, subaccounts, valuation methods, lot and serial numbers, storage locations, and other values.

ACCELERATE DECISION- MAKING

- Use drill-down reports and dashboards to spot trends.

- Identify low and dead-stock items.

- Analyze profitability by item and product class or family.

Features and Capabilities

REPLENISHMENT

Define min and max order quantities, reorder points, seasonality, lead times, safety stock, and forecast models to calculate replenishment.

TRANSACTION REASON CODES

Measure trends and spot problems by assigning reason codes to inventory transactions. Reason codes can be linked to both general ledger (GL) accounts and inventory levels for financial and operational reporting.

LOCATION MANAGEMENT

Setup and manage multiple warehouse locations with stocking locations defined by aisle, row, rack, slot, and bin. Define location defaults for receiving, returns, shipping, and drop-shipment transactions. Prioritize pick locations by item and by the warehouse.

TWO-STEP TRANSFERS

Inventory transfers are performed in two steps so you can track goods in transit between locations with GL entries into and out of “in transit” accounts.

SUB-ITEMS AND MATRIX ITEMS

Create and manage matrix items based on size, color, and other attributes and values. Matrix items streamline item management, purchasing, and sales processes. Use matrix views to update prices and descriptions for items in the matrix item product family. Setup sub item codes by SKU to differentiate between product variations such as grade, manufacturer, or other variables.

INVENTORY BIN/LOCATION CONTROL

PHYSICAL INVENTORY

Create movement classes and ABC rank codes to determine physical inventory frequency.

PURCHASE ORDER AUTOMATION

Automatically generate purchase orders based on stock level and replenishment algorithms. Orders go to the vendor with the best price and delivery time.

CRM INTEGRATION

Convert CRM opportunities to sales orders without re-entering pricing and discount information. Customer service can locate orders to verify shipping and delivery status.

PRICING, DISCOUNTS, AND PROMOTIONS

Manage complex pricing and discount policies, including volume discounts and multiple discounts per item. Maintain policies for price overrides, customer pricing, and commissions.

CUSTOMER AND VENDOR ITEMS

Define unlimited vendors by item with a preferred default vendor. Set a minimum frequency for deliveries and minimum or maximum order quantities by item for each vendor. Define cross-references between internal, vendor, and customer items.

PACKAGING AND UOM

Define variable packaging for inventory items with standard and configurable unit of measure conversions for weight and volume.

SHIPMENTS

Manage shipments with small parcel carriers such as FedEx, UPS, Stamps.com for United States Postal Service shipments, and LTL carriers with EasyPost.

KITTING AND DISASSEMBLY

Build kits to stock or to order. Disassemble kits into components.

PERISHABLE INVENTORY AND LOT/SERIAL TRACEABILITY

Use shelf life and expiration dates to manage perishable inventory with first-expired-first-out (FEFO) picking. Capture and create lot and serial numbers for traceable inventory.