Discrete and Process Manufacturing

Acumatica Material Requirements Planning (MRP)

Home » ERP Resources » Acumatica Resources » Acumatica MRP

Satisfy Customer Requirements While Maintaining Optimal Inventory Levels Using the Powerful Acumatica Manufacturing Edition MRP Planning Tool

Generate time-phased manufacturing and purchasing plans for optimal inventory availability tied to forecast and customer demands. Reduce inventory while improving customer service and avoiding shortages.

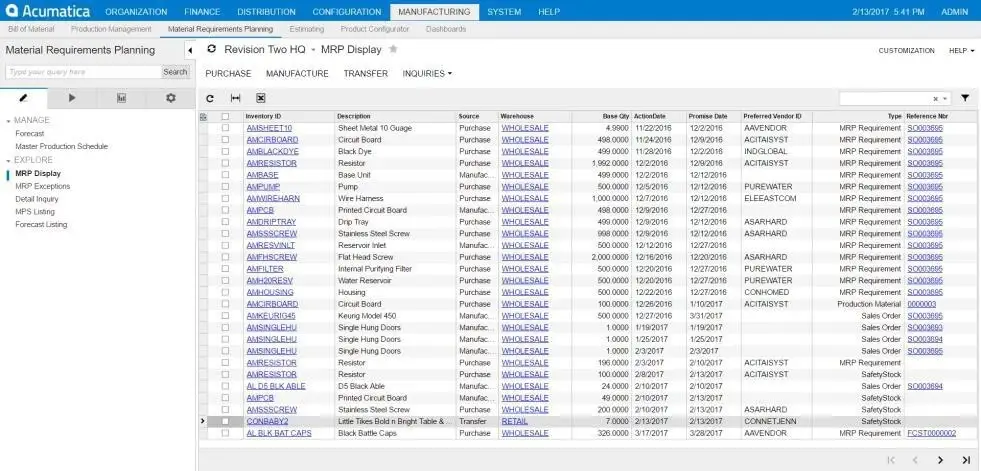

MRP DISPLAY

- This core MRP screen shows the planner exactly what needs to be purchased and/or produce

- All supply and demand can be viewed from this one centralized location

- Production and Purchase Orders can be created directly from this screen

FULL REGENERATION

- Schedule regeneration to run anytime, day or night

- All existing planned orders for all items are eliminated.

- MRP starts over, calculating gross and net requirements, and then replans what materials are required to either be produced or purchased.

MASTER PRODUCTION SCHEDULE

- Drive your plan and your plant from the Master Production Schedule (MPS).

- MRP plans all requirements based upon MPS.

- MPS will be treated as a pre-planned production order and will act as a supply

Key Benefits

COORDINATE ACTIVITIES

- Manage your entire business with complete, real-time information for your operations

- Coordinate labor, machines, and inventory and optimize your company’s processes

STAY ON ONE PLATFORM AS YOU GROW

- Adapt the software to meet your changing needs

- Leverage powerful features and functions for multiple production environments

MRP EXCEPTION MESSAGES HANDLE PROBLEMS WITH EASE

- Shows the planner recommendations to defer, expedite, and delete supply items

- Identify late orders and display any transfers that are available from another warehouse or site

Features and Capabilities

FORECASTING

Forecasts can be calculated or entered manually. These forecasts can be dependent and consumed by sales orders, or they can be independent. Input forecasts as one-time, weekly, monthly, or yearly.

BUCKETLESS SYSTEM

Enhance your manufacturing resource planning by planning every requirement for every item. Acumatica MRP does not ignore detail by grouping requirements together.

MULTI-SITE PLANNING

Controls whether MRP will plan requirements by site or by a combination of sites.