The Acumatica WMS (warehouse management system) module included in the Distribution Edition suite offers several tools to help you streamline your inventory and supply chain processes from one end to the other, no matter how many warehouses you have. Drawing from real-world implementations, this blog will walk you through the steps for setting up the warehouse automation system in Acumatica Cloud ERP along with other tips and tricks for getting the most out of this module’s capabilities:

Setting Up Your Warehouse(s) in Acumatica

By carefully configuring your warehouse structure at the top level, you will be able to grant consistent visibility to the appropriate teams and make it easier to automate connected processes down the line when time is limited. This section will walk you through the basic steps for achieving this and establishing your master-level view in Acumatica WMS and connected module screens.

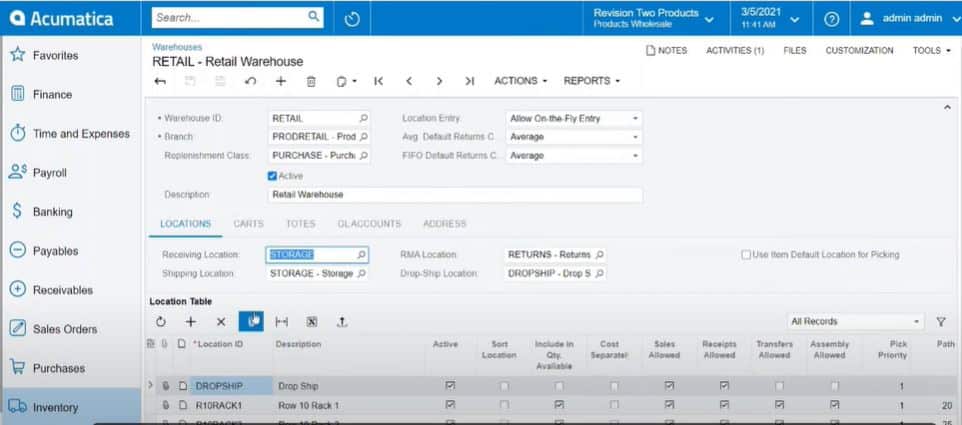

First, you will want to configure your warehouse IDs and naming conventions. Choose clear, logical names that reflect your physical warehouse structure. Next, create and manage warehouse locations, including bins and shelves. Set up default locations for critical processes such as shipping, receiving, and returns. Finally, implement bin locations to optimize storage and picking efficiency.

Key setup steps for Acumatica WMS:

- Configure warehouse IDs and naming conventions

- When creating locations, use a logical naming structure such as “Row 1, Shelf 1”

- Create and manage warehouse locations

- Set up default locations for shipping, receiving, and RMA

- Set location-specific parameters like allowing sales, receipts, or transfers

- Implement bin locations for optimized storage

- Select and designate shipping providers, including UPS and FedEx

Inventory Management

Acumatica WMS connects seamlessly with the Inventory Management module and lets you synchronize data between both in up to real-time, automatically populating appropriate fields and updating reports with the right settings. This integration allows you to monitor stock levels, automate replenishment, and ensure that inventory is allocated correctly across all warehouses.

Begin by assigning the valuation method you need for a given product line, such as FIFO, moving average, or standard cost. Implement inventory replenishment suggestions to maintain optimal stock levels based on historical data. Utilize subitems to track product variations like size, color, or style. Finally, set up lot and serial number tracking for improved traceability and quality control.

Acumatica Inventory Management lets you:

- Track inventory levels across multiple warehouses

- Select from valuation methods: standard cost, moving average, FIFO, or item-specific

- Use inventory replenishment suggestions based on historical data

- Set up matrix items to track product variations (size, color, style)

- Setup sub item codes by SKU to differentiate between product variations such as grade, manufacturer, or other variables

- Implement lot and serial number tracking

- Deduct expired items from your list of available inventory by assigning an expiration date for each lot and serial number

- Use ABC codes and movement classes for physical inventory counts

- Use shelf life and expiration dates to manage perishable inventory with first-expired-first-out (FEFO) picking

Sales Order Management

Acumatica WMS lets you integrate directly with the Sales Order (SO) module and automatically sync data flows from order creation to fulfillment. Other sales functionality includes entering quotes, fulfilling sales orders, creating shipments, tracking prices, applying discounts, and checking available inventory. This integration allows your users to manage these different sales activities across your warehouse locations and throughout your value chain without having to jump between multiple apps and screens.

Start by optimizing your sales order creation and management processes. Implement automated workflows to eliminate unnecessary steps and reduce manual intervention. Configure flexible discounts and promotions to enhance your pricing strategy. Finally, optimize your pick, pack, and ship process using Acumatica’s advanced features, such as wave picking and barcode scanning.

Connected order processing features:

- Automatically convert CRM opportunities into sales orders

- Configure discounts and promotions

- Use barcode scanners to create pick lists

- Establish packing rules for each item

- Automatically generate shipping labels and track shipments

- Ensure correct allocation of inventory to orders

- Drill-down into historical data on past sales

Purchase Order Management

Connecting the Acumatica Purchase Order (PO) module with your WMS enables your team to keep an eye on inventory levels and set up automated workflows for actions like replenishment, order approval, and blanket orders. With the PO module integrated with WMS, can streamline your procurement processes to ensure a steady supply of materials while enforcing policy and process controls.

Begin by setting up automatic purchase order creation based on inventory levels and replenishment algorithms. Implement multi-level approvals to maintain control over spending and ensure compliance with company policies. Manage blanket orders to take advantage of volume discounts and secure better pricing from vendors. Lastly, streamline the receive and put away process using barcode scanning and mobile devices for increased accuracy and efficiency.

PO automation features include:

- Set up automatic purchase order creation based on inventory levels

- Implement multi-level approvals

- Use blanket orders for volume discounts

- Streamline receive and put away process with barcode scanning

- Link sales orders with purchase orders so received items can be allocated to orders

- Create drop shipments to deliver goods directly to a customer location

Acumatica General Ledger

The Acumatica Financial Management module allows data from WMS and Inventory Management is posted to the General Ledger (GL) for consistent and automated reporting. Acumatica’s GL acts as the central hub of your accounting data, including your Chart of Accounts (COA), financial periods, journal entries, allocations, and more.

Integrated General Ledger allows:

- Automatically post transactions to the GL

- Create real-time financial reports

- Control which users can view and create transactions for specific GL accounts

- Assign roles to approve transactions, release transactions, and close periods

- Enter GL transactions in different currencies by activating multiple currency support

- Create codes and Classes for each stock item, customer and vendor account

Other Acumatica Warehouse Management Features

Acumatica WMS features additional functionality at all levels, including handling multiple orders with wave or batch picking, moving inventory between multiple warehouses, assigning classes to items or vendors, tracking discrepancies between orders and reports, and much more.

Additional WMS features:

- Wave and batch picking for bulk orders

- Best path calculation for optimized picker routes

- Seamless inventory transfers between warehouses

- Create sales quotes based on catalog pricing or cost plus algorithms

- Implement substitution logic for out-of-stock items

- Attach notes and documentation to inventory records

- Track discrepancies, such as damaged goods

- Notify customers of shipment progress through each stage of order fulfillment

- Add Device Hub for printer integration

- Integrate EDI to ensure compliance with partner requirements

- Including 856 Advance Ship Notice (ASN)

WMS Mobile Functionality

The Acumatica Mobile App – available on Android and iOS devices – includes direct access to WMS and connected features, allowing users to view or create reports, manage approvals, scan barcodes and other actions from their smartphone. Train your team to perform pick, pack, and ship processes using mobile devices. Implement mobile receiving and put away processes to streamline inbound operations and reduce data entry errors.

Mobile WMS capabilities:

- Perform pick, pack, and ship processes on mobile devices

- Manage receiving and put away on the go

- Update order statuses and inventory levels from your smartphone

- Enable employees to enter time and expenses or review cases on the go

Reporting and Analytics in Acumatica

Acumatica offers robust reporting and analytics tools to help you gain insights into your inventory, sales, projects and more from all connected sides of your business. For the WMS module, this includes being able to create real-time inventory reports to identify potential stockouts or overstock situations. Examples of other reporting features include analyzing profitability by warehouse, product line, or location to identify areas for improvement, or implementing ABC analysis for inventory optimization, focusing your efforts on high-value or fast-moving items.

With Acumatica’s reporting analytics, you can:

- Access real-time inventory reports

- View profitability analysis by warehouse, product line, or location

- Use ABC analysis for inventory optimization

- Customize dashboards for role-based KPIs

- Define stock and non-stock items as their own class and link to each other

- Automate data entry en masse to automatically populate multiple fields across similar reports

Discover More Tips, Tricks and Demos for Acumatica

SWK Technologies will help you get the most out of your ERP investment, leveraging our deep technological and industry knowledge as a top Acumatica partner and Community resource. Check out some of our Acumatica videos and other educational resources, and reach out to us when you’re ready to learn more tips and tricks to maximize your value return on your software.

Contact SWK here to gain access to more Acumatica tips, tricks, updates, and tailored demos.