ERP & Accounting Software

Manufacturing Operations for Sage Intacct

Home » Products » Sage Intacct » Manufacturing Operations for Sage Intacct

Navigating Excellence in Production

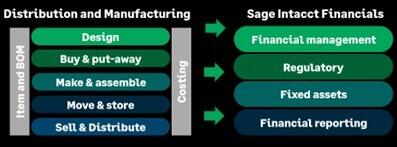

Distribution and Manufacturing Operations for Sage Intacct offers robust capabilities to streamline and optimize the complex processes involved in the production and distribution of goods. This platform provides comprehensive tools and features designed to enhance efficiency, visibility, and control across the supply chain. Additionally, SDMO integrated with Sage Intacct ensures seamless general ledger, accounts payable and accounts receivable journal and bill transfers.

Designed with Manufacturers in Mind

In the intricate dance of modern manufacturing, efficiency, precision, and adaptability are paramount. As the manufacturing landscape evolves, so do the tools that drive operational excellence. Sage, a renowned name in the world of business solutions, offers a comprehensive suite of software and tools tailored to optimize manufacturing operations.

Unveiling Manufacturing Operations for Sage Intacct

Encompassing a suite of solutions designed to empower businesses to streamline their production processes, Manufacturing Operations for Sage Intacct spans inventory management and production planning to quality control and analytics. Manufacturers will be equipped with the tools needed to optimize efficiency, reduce costs, and stay competitive in a fast-paced market.

Key Benefits of Manufacturing Operations for Sage Intacct:

Efficient Production Planning

This solution offers real-time insights into production schedules, enabling businesses to plan and allocate resources effectively. This optimization minimizes production bottlenecks and maximizes resource utilization.

Inventory Management

Manufacturers will gain a holistic view of their inventory levels, ensuring that raw materials and finished goods are maintained at optimal levels. This prevents overstocking, reduces waste, and improves cash flow.

Quality Control and Compliance

Features tools which facilitate stringent quality control processes, ensuring that products meet industry standards and customer expectations. Compliance tracking and reporting help manufacturers stay in line with regulatory requirements.

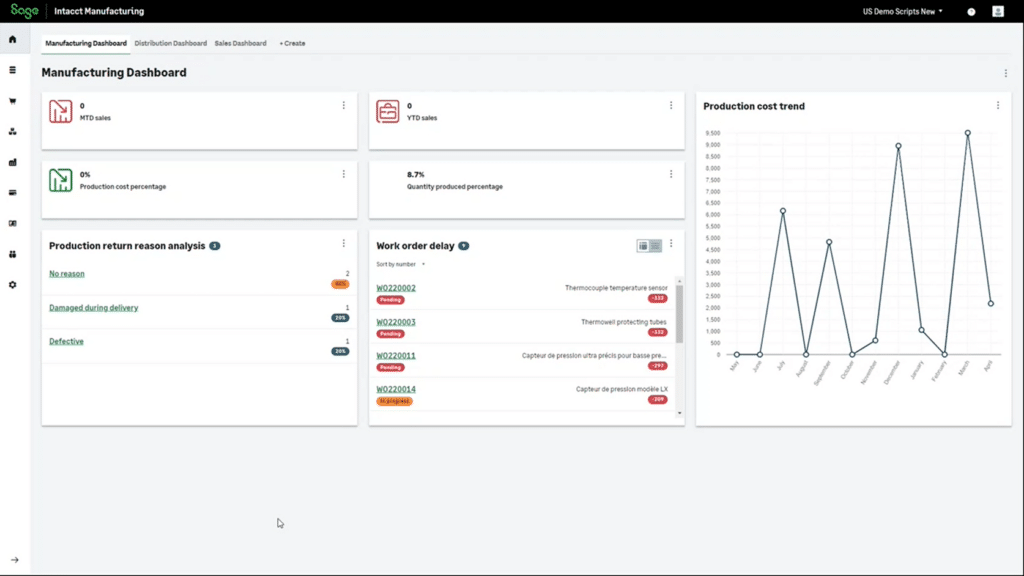

Real-time Analytics

Manufacturing operations generate a wealth of data. Analytic capabilities transform this data into actionable insights, enabling manufacturers to make informed decisions, identify areas for improvement, and optimize their processes continuously.

Responsive Supply Chain

Supply chain visibility is enhanced, enabling manufacturers to respond swiftly to changing market demands and unforeseen disruptions. This agility is critical in a world where adaptability is key to success.

Strategies for Maximizing Manufacturing Operations for Sage Intacct:

Holistic Integration

Integrating solutions seamlessly with existing systems is crucial. Collaborate closely with your IT team and SWK Technologies experts to ensure a smooth integration process that minimizes disruptions.

Customization for Fit

Tailor the software to align with your unique manufacturing processes. Customizations ensure that the tools work in harmony with your business model, boosting efficiency and accuracy.

Employee Empowerment

Comprehensive training is essential for your manufacturing team. Ensure that employees are well-trained to leverage Sage tools effectively and encourage a culture of continuous learning.

Continuous Improvement Culture

Manufacturing operations are a journey of improvement. Regularly evaluate your processes, analyze performance metrics from Manufacturing Operations for Sage Intacct’s reporting features, and implement refinements to drive operational excellence.

Collaboration and Communication

Foster collaboration between different departments involved in manufacturing. Clear communication channels ensure that everyone is aligned, working towards common goals, and contributing to the overall success of manufacturing operations.